What is a butt weld elbow? A butt weld elbow is a type of pipe fitting used to change the

ASME B16.47 Class 150 Series B flanges are commonly produced using various materials suitable for different industrial applications. Some frequently used materials for these flanges include:

1. Carbon Steel (ASTM A105): Known for its strength and adaptability to high-pressure and high-temperature environments.

2. Stainless Steel (ASTM A182): Offers excellent resistance to corrosion, making it ideal for applications in corrosive settings.

3. Alloy Steel (ASTM A182 F11, F22): Exhibits superior mechanical properties and resistance to elevated temperatures, suitable for demanding conditions.

4. Duplex Stainless Steel: Combines strength and corrosion resistance, making it suitable for challenging environments.

5. Nickel Alloys (Inconel, Monel, Hastelloy): Used in extreme conditions with high temperatures, pressure, and corrosive media.

Common dimensions and specifications for ASME B16.47 Class 150 Series B flanges typically range from NPS 26 (Nominal Pipe Size) to NPS 60, with pressure ratings designated at Class 150.

Production processes for manufacturing these flanges involve precision machining, forging, or casting methods to ensure compliance with ASME standards. Heat treatment processes are also employed to enhance material properties, such as hardness and durability.

The application scope of ASME B16.47 Class 150 Series B flanges spans various industries, including oil and gas, petrochemicals, chemical processing, power generation, and more. These flanges are utilized in situations where high-pressure and high-temperature conditions are prevalent, ensuring reliable and secure connections in piping systems.

FAQs related to ASME B16.47 Class 150 Series B flanges include:

1. What are the temperature and pressure limitations for different materials used in Class 150 Series B flanges?

– Temperature and pressure limitations vary based on the material used in Class 150 Series B flanges. For instance, carbon steel (ASTM A105) flanges are rated for Class 150 at temperatures up to 455°C (850°F) and lower temperatures at Class 300. Stainless steel, alloy steel, and other materials have their specific temperature and pressure ratings as per ASME standards.

2. Can Class 150 Series B flanges be used interchangeably with flanges of other pressure classes?

– ASME B16.47 Class 150 Series B flanges follow standard dimensions and specifications, allowing some degree of interchangeability with flanges of the same nominal size and facing type but within the same pressure class. However, it’s crucial to verify compatibility based on specific application requirements and standards.

3. What quality control measures are employed during the manufacturing process of these flanges?

– The manufacturing process typically includes stringent quality control measures such as material traceability checks, dimensional inspections, non-destructive testing (NDT) methods like ultrasonic testing, radiographic examination, dye penetrant testing, and pressure testing to ensure compliance with ASME standards and the desired quality of the flanges.

4. Are there specific guidelines for installation and maintenance of Class 150 Series B flanges?

– Yes, installation and maintenance guidelines conforming to ASME standards are essential. These guidelines typically include proper bolt torque specifications, gasket selection, alignment procedures, and adherence to recommended installation practices to ensure leak-free and secure connections.

5. How do these flanges compare in terms of longevity and performance in aggressive environments compared to lower-class flanges?

– Class 150 Series B flanges are designed to withstand higher pressures and temperatures compared to lower-class flanges. The choice of materials and their specific properties contributes significantly to longevity and performance in aggressive environments, providing enhanced resistance to corrosion, high temperatures, and pressure, ensuring reliability and durability.

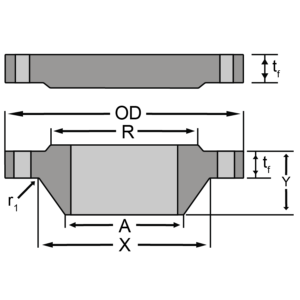

| Nominal Size | Outside Diameter | Min. Thickness [Note1] – WNF | Min. Thickness [Note1] – Blind | Length Through Hub | Hub Dia. Base [Note2] | Hub Dia. Top | Raised Face Dia. | Drilling – Bolt Circle Dia. | Drilling – No. of Bolt Holes | Drilling – Dia. of Bolt Hole | Dia. of Bolt | Min. Fillet Radius |

| (OD) | (tf) | (tf) | (Y) | (X) | (A) | (R) | (r1) | |||||

| 26 | 30.94 | 1.57 | 1.69 | 3.44 | 26.94 | 26.06 | 28 | 29.31 | 36 | 7⁄8 | 3⁄4 | 0.38 |

| 28 | 32.94 | 1.69 | 1.82 | 3.69 | 28.94 | 28.06 | 30 | 31.31 | 40 | 7⁄8 | 3⁄4 | 0.38 |

| 30 | 34.94 | 1.69 | 1.94 | 3.88 | 31 | 30.06 | 32 | 33.31 | 44 | 7⁄8 | 3⁄4 | 0.38 |

| 32 | 37.06 | 1.75 | 2.07 | 4.19 | 33.06 | 32.06 | 34 | 35.44 | 48 | 7⁄8 | 3⁄4 | 0.38 |

| 34 | 39.56 | 1.88 | 2.19 | 4.28 | 35.12 | 34.06 | 36.25 | 37.69 | 40 | 1 | 7⁄8 | 0.38 |

| 36 | 41.62 | 2 | 2.25 | 4.57 | 37.19 | 36.06 | 38.25 | 39.75 | 44 | 1 | 7⁄8 | 0.38 |

| 38 | 44.25 | 2.07 | 2.44 | 4.82 | 39.25 | 38.12 | 40.25 | 42.12 | 40 | 11⁄8 | 1 | 0.38 |

| 40 | 46.25 | 2.13 | 2.57 | 5 | 41.31 | 40.12 | 42.5 | 44.12 | 44 | 11⁄8 | 1 | 0.38 |

| 42 | 48.25 | 2.25 | 2.63 | 5.19 | 43.38 | 42.12 | 44.5 | 46.12 | 48 | 11⁄8 | 1 | 0.44 |

| 44 | 50.25 | 2.32 | 2.75 | 5.32 | 45.38 | 44.12 | 46.5 | 48.12 | 52 | 11⁄8 | 1 | 0.44 |

| 46 | 52.81 | 2.38 | 2.88 | 5.63 | 47.44 | 46.12 | 48.62 | 50.56 | 40 | 11⁄4 | 11⁄8 | 0.44 |

| 48 | 54.81 | 2.5 | 3 | 5.82 | 48.5 | 48.12 | 50.75 | 52.56 | 44 | 11⁄4 | 11⁄8 | 0.44 |

| 50 | 56.81 | 2.63 | 3.13 | 6 | 51.5 | 50.12 | 52.75 | 54.56 | 48 | 11⁄4 | 11⁄8 | 0.44 |

| 52 | 58.81 | 2.69 | 3.25 | 6.13 | 53.56 | 52.12 | 54.75 | 56.56 | 52 | 11⁄4 | 11⁄8 | 0.44 |

| 54 | 61 | 2.75 | 3.38 | 6.32 | 55.62 | 54.12 | 56.75 | 58.75 | 56 | 11⁄4 | 11⁄8 | 0.44 |

| 56 | 63 | 2.82 | 3.5 | 6.5 | 57.69 | 56.12 | 58.75 | 60.75 | 60 | 11⁄4 | 11⁄8 | 0.56 |

| 58 | 65.94 | 2.88 | 3.62 | 6.82 | 59.69 | 58.12 | 60.75 | 63.44 | 48 | 13⁄8 | 11⁄4 | 0.56 |

| 60 | 67.94 | 2.94 | 3.75 | 7 | 61.81 | 60.12 | 63 | 65.44 | 52 | 13⁄8 | 11⁄4 | 0.56 |

Notes

Dimensions are in inches.

1) The minimum flange thickness does not include the raised face thickness

2) This dimension is for the large end of hub, which may be straight or tapered.

3) WN ID/Bore is to be specified by purchaser.

4) For other details and tolerances see specification.

Sino Special Metal offers a comprehensive range of ASME B16.47 Class 150 Series B flanges, providing expert consultation and guidance for customers seeking reliable and durable flange solutions. With an emphasis on diverse material options, precise manufacturing techniques, and adherence to industry standards, Sino Special Metal ensures top-notch flange solutions for various demanding applications. Feel free to inquire for tailored solutions and procurement assistance.

What is a butt weld elbow? A butt weld elbow is a type of pipe fitting used to change the

At SINO SPECIAL METAL, we provide high-quality butt weld eccentric reducers, essential fittings used in piping systems to seamlessly connect

What is a Butt Weld Concentric Reducer At SINO SPECIAL METAL, we offer high-quality butt weld concentric reducers, pivotal components

SSM stands as a premier supplier enterprise, renowned for its specialization in crafting high-quality special metal products. Our commitment to excellence and precision in production ensures that your unique metal requirements are not just met but exceeded. Discover the quality that defines SSM as a leading name in the industry.