What is a butt weld elbow? A butt weld elbow is a type of pipe fitting used to change the

Common Materials:

– Carbon Steel: ASTM A105/A350 LF2

– Stainless Steel: ASTM A182 F304/F316

– Alloy Steel: ASTM A182 F11/F22

Common Dimensions:

– Size Range: Typically above 26″ up to 60″ (DN650-DN1500) or larger

– Pressure Rating: Class 400 (400 PSI)

– Flange Facings: Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF)

Share:

ASME B16.47 Class 400 Series A Flanges are heavy-duty flanges designed to withstand high pressure in critical industrial applications. These flanges conform to the American Society of Mechanical Engineers (ASME) standards and are rated for Class 400 pressure, belonging to Series A with larger dimensions compared to Series B.

Common Materials:

– Carbon Steel: ASTM A105/A350 LF2

– Stainless Steel: ASTM A182 F304/F316

– Alloy Steel: ASTM A182 F11/F22

Common Dimensions:

– Size Range: Typically above 26″ up to 60″ (DN650-DN1500) or larger

– Pressure Rating: Class 400 (400 PSI)

– Flange Facings: Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF)

Production Processes:

Manufacturing ASME B16.47 Class 400 Series A Flanges involves precision machining and forging processes tailored for larger diameters. Forged raw materials such as carbon steel, stainless steel, or alloy steel undergo shaping using forging machinery and precise machining to meet stringent dimensional requirements. CNC machining ensures accuracy and quality.

Applications:

These flanges are utilized in heavy industries requiring extremely high-pressure piping systems, such as oil and gas refineries, chemical processing plants, and power generation facilities. They are specifically employed in pipelines carrying fluids or gases under very high pressure and temperature conditions.

Common Q&A:

1. Why choose Class 400 Series A flanges?

– Class 400 flanges are designed to withstand significantly higher pressures, ensuring the integrity and safety of piping systems in extremely demanding applications compared to lower pressure-rated flanges.

2. How do Series A and Series B flanges differ in ASME B16.47?

– Series A flanges have larger dimensions compared to Series B, allowing for more space for welding and accommodating larger-sized pipes.

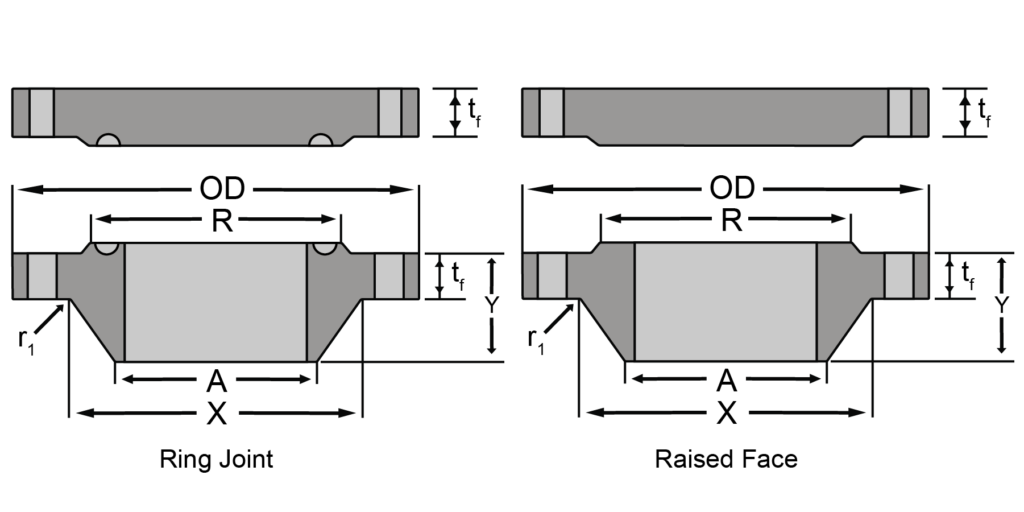

| Nominal Size | Outside Diameter | Min. Thickness [Note1] – WNF | Min. Thickness [Note1] – Blind | Length Through Hub | Hub Dia. Base [Note2] | Hub Dia. Top | Raised Face Dia. | Drilling – Bolt Circle Dia. | Drilling- No. of Bolt Holes | Drilling – Dia. of Bolt Hole | Dia. of Bolt | Min. Fillet Radius |

| (OD) | (tf) | (tf) | (Y) | (X) | (A) | (R) | (r1) | |||||

| 26 | 38.25 | 3.5 | 3.88 | 7.62 | 28.62 | 26 | 29.5 | 34.5 | 28 | 17⁄8 | 13⁄4 | 0.44 |

| 28 | 40.75 | 3.75 | 4.12 | 8.12 | 30.81 | 28 | 31.5 | 37 | 28 | 2 | 17⁄8 | 0.5 |

| 30 | 43 | 4 | 4.38 | 8.62 | 32.94 | 30 | 33.75 | 39.25 | 28 | 21⁄8 | 2 | 0.5 |

| 32 | 45.25 | 4.25 | 4.56 | 9.12 | 35 | 32 | 36 | 41.5 | 28 | 21⁄8 | 2 | 0.5 |

| 34 | 47.5 | 4.38 | 4.81 | 9.5 | 37.19 | 34 | 38 | 43.5 | 28 | 21⁄8 | 2 | 0.56 |

| 36 | 50 | 4.5 | 5.06 | 9.88 | 39.38 | 36 | 40.25 | 46 | 32 | 21⁄8 | 2 | 0.56 |

| 38 | 47.5 | 4.88 | 4.88 | 8.12 | 39.5 | 38 | 40.75 | 44 | 32 | 17⁄8 | 13⁄4 | 0.56 |

| 40 | 50 | 5.12 | 5.12 | 8.5 | 41.5 | 40 | 43 | 46.25 | 32 | 2 | 17⁄8 | 0.56 |

| 42 | 52 | 5.25 | 5.25 | 8.81 | 43.62 | 42 | 45 | 48.25 | 32 | 2 | 17⁄8 | 0.56 |

| 44 | 54.5 | 5.5 | 5.5 | 9.18 | 45.62 | 44 | 47.25 | 50.5 | 32 | 21⁄8 | 2 | 0.56 |

| 46 | 56.75 | 5.75 | 5.75 | 9.62 | 47.75 | 46 | 49.5 | 52.75 | 36 | 21⁄8 | 2 | 0.56 |

| 48 | 59.5 | 6 | 6 | 10.12 | 49.88 | 48 | 51.5 | 55.25 | 28 | 23⁄8 | 21⁄4 | 0.56 |

| 50 | 61.75 | 6.19 | 6.25 | 10.56 | 52 | 50 | 53.62 | 57.5 | 32 | 23⁄8 | 21⁄4 | 0.56 |

| 52 | 63.75 | 6.38 | 6.44 | 10.88 | 54 | 52 | 55.62 | 59.5 | 32 | 23⁄8 | 21⁄4 | 0.56 |

| 54 | 67 | 6.69 | 6.75 | 11.38 | 56.12 | 54 | 57.88 | 62.25 | 28 | 25⁄8 | 21⁄2 | 0.56 |

| 56 | 69 | 6.88 | 6.94 | 11.75 | 58.25 | 56 | 60.12 | 64.25 | 32 | 25⁄8 | 21⁄2 | 0.56 |

| 58 | 71 | 7 | 7.12 | 12.06 | 60.25 | 58 | 62.12 | 66.25 | 32 | 25⁄8 | 21⁄2 | 0.56 |

| 60 | 74.25 | 7.31 | 7.44 | 12.56 | 62.38 | 60 | 64.38 | 69 | 32 | 27⁄8 | 23⁄4 | 0.56 |

Notes

Dimensions are in inches.

1) The minimum flange thickness does not include the raised face thickness

2) This dimension is for the large end of hub, which may be straight or tapered.

3) Weldneck Bore/ID is to be specified by purchaser

4) For other details and tolerances see specification.

Sino Special Metal Supply offers ASME B16.47 Class 400 Series A Flanges suitable for critical industrial applications. Their flanges comply with international standards, ensuring reliability and performance in extremely high-pressure piping systems. Customers are encouraged to inquire about specific material grades, sizes, or custom requirements for their projects.

What is a butt weld elbow? A butt weld elbow is a type of pipe fitting used to change the

At SINO SPECIAL METAL, we provide high-quality butt weld eccentric reducers, essential fittings used in piping systems to seamlessly connect

What is a Butt Weld Concentric Reducer At SINO SPECIAL METAL, we offer high-quality butt weld concentric reducers, pivotal components

SSM stands as a premier supplier enterprise, renowned for its specialization in crafting high-quality special metal products. Our commitment to excellence and precision in production ensures that your unique metal requirements are not just met but exceeded. Discover the quality that defines SSM as a leading name in the industry.