What is a butt weld elbow? A butt weld elbow is a type of pipe fitting used to change the

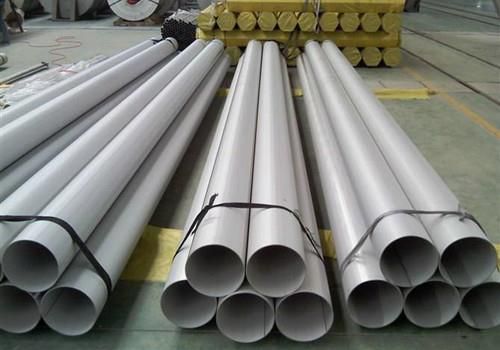

The American Society for Testing and Materials (ASTM) has established a specification known as ASTM A312 that applies to both seamless and welded stainless steel pipes. ASTM A312 pipes are highly regarded for their quality, meeting strict standards to ensure they can withstand a range of demanding applications. This detailed guide explores ASTM A312 pipes, including their production specifications, production technology, main materials, main types, application fields, and their advantages and disadvantages.

ASTM A312 specifies the requirements for seamless and welded stainless steel pipes, ensuring they meet high-quality standards. Key production specifications encompass:

1. Size: ASTM A312 pipes are available in various sizes, measured by their nominal pipe size (NPS), which represents their outside diameter.

2. Wall Thickness: The specification defines the minimum wall thickness of pipes, ensuring they can withstand various pressures and stresses.

3. Heat Treatment: ASTM A312 may require heat treatment to improve mechanical properties and corrosion resistance.

4. Testing: Rigorous testing for quality control, including non-destructive examination methods like ultrasonic testing or hydrostatic testing, is mandated.

5. Surface Finish: The standard can specify surface finishes, including mill finish, mechanical polished, or electropolished, to meet specific application requirements.

The manufacturing process of ASTM A312 pipes involves multiple steps:

1. Melting: High-quality raw materials, primarily iron, chromium, and nickel, are melted in an electric arc furnace to create stainless steel.

2. Casting: The molten steel is cast into billets or slabs.

3. Hot Rolling: Billets or slabs are heated and passed through rollers to reduce their thickness and achieve the desired size.

4. Cold Drawing or Cold Rolling: To refine dimensions and improve surface finish, pipes are cold-drawn or cold-rolled.

5. Heat Treatment: Some pipes undergo heat treatment to enhance their mechanical properties and corrosion resistance.

6. Cutting and Finishing: Pipes are cut to the desired length, and their ends may be deburred and polished.

ASTM A312 pipes are primarily made from various grades of stainless steel, offering a range of properties suitable for diverse applications. Common stainless steel grades used in ASTM A312 pipes include:

1. Austenitic stainless steel: Grades like 304, 304L, 316, and 316L are known for being very resistant to corrosion, easy to shape, and good for uses that will be exposed to high temperatures or corrosive environments.

2. Ferritic Stainless Steel: Grades like 409, 430, and 439 provide good resistance to corrosion and oxidation, often used in applications where aesthetic appearance is less critical.

3. Duplex Stainless Steel: Duplex grades like 2205 combine the best features of both austenitic and ferritic stainless steel, offering high strength, good corrosion resistance, and improved stress corrosion cracking resistance.

4. Martensitic Stainless Steel: Grades like 410 and 420 are valued for their high hardness and wear resistance, making them suitable for applications where durability is essential.

ASTM A312 covers a variety of pipe types, each tailored to specific applications:

1. Seamless Pipes: These pipes are manufactured without seams, known for their strength and suitability for high-pressure applications.

2. Welded Pipes: Made from welding strips or plates, welded pipes are more affordable and suitable for a variety of applications.

3. Round Pipes: The most common shape, used in diverse industries for conveying fluids and structural purposes.

4. Square Pipes: Ideal for architectural and structural applications, offering a modern and aesthetic appeal.

5. Rectangular Pipes: Used in construction, furniture, and architectural applications due to their rectangular cross-section.

6. Oval Pipes: Uniquely shaped for specific aesthetic and structural purposes.

ASTM A312 pipes find applications in a variety of industries, due to their exceptional qualities:

1. Construction: Used in building structures, plumbing, and architectural features due to their corrosion resistance, durability, and aesthetic appeal.

2. Petrochemical: Essential for transporting corrosive fluids and gases in refineries and chemical processing plants.

3. Automotive: Stainless steel pipes are used in exhaust systems, fuel lines, and structural components due to their corrosion resistance and heat resistance.

4. Food and Beverage: In the food processing and beverage industries, ASTM A312 pipes ensure product purity, hygiene, and compliance with regulatory standards.

5. Pharmaceutical: Used in the pharmaceutical industry to ensure sterile and uncontaminated product manufacturing.

6. Aerospace: Used in aircraft and spacecraft due to their lightweight yet strong properties.

7. Marine: Stainless steel’s resistance to saltwater corrosion makes it essential in the maritime industry for various applications.

8. Energy: ASTM A312 pipes are critical in nuclear, geothermal, and solar power plants due to their durability and heat resistance.

ASTM A312 pipes offer several advantages that make them a preferred choice in numerous applications:

1. High-Quality Standards: ASTM A312 ensures pipes meet strict quality and performance standards, providing peace of mind for end-users.

2. Corrosion Resistance: These pipes are highly resistant to corrosion, making them ideal for use in harsh and corrosive environments.

3. Versatility: ASTM A312 covers a wide range of stainless steel grades and types, allowing for customization to meet specific application needs.

4. Aesthetic Appeal: The option for polished and electropolished finishes ensures these pipes are suitable for decorative and architectural applications.

5. High Strength: Stainless

steel pipes exhibit excellent mechanical properties, making them suitable for high-stress applications.

6. Hygienic: Smooth surfaces are easy to clean and maintain, making them suitable for industries with strict hygiene requirements.

7. Temperature Resistance: These pipes can withstand extreme temperatures, ensuring suitability for both high- and low-temperature applications.

8. Recyclability: Stainless steel is 100% recyclable, reducing environmental impact and promoting sustainability.

While ASTM A312 pipes offer numerous advantages, there are some limitations to consider:

1. Cost: Stainless steel can be more expensive than other materials, potentially impacting project budgets, especially in large-scale applications.

2. Weight: Stainless steel is denser than materials like aluminum, which can lead to increased weight in some applications.

3. Magnetism: Some stainless steel grades are magnetic, which may not be desirable in specific applications.

4. Welding Challenges: Certain grades may require specialized welding techniques and expertise.

In summary, ASTM A312 pipes represent a top-tier choice for various industries due to their remarkable characteristics, such as corrosion resistance, strength, and aesthetic appeal. With various types, grades, and production standards available, ASTM A312 pipes can be tailored to meet the specific needs of any project. As a leading supplier of ASTM A312 pipes, Sino Special Metal is dedicated to providing high-quality products that conform to ASTM A312 specifications, backed by expert knowledge and extensive experience in the field.

If you’re seeking premium ASTM A312 pipes that align with your specific project requirements, look no further than Sino Special Metal. With our extensive product range and commitment to quality, we are the trusted partner for all your ASTM A312

What is a butt weld elbow? A butt weld elbow is a type of pipe fitting used to change the

At SINO SPECIAL METAL, we provide high-quality butt weld eccentric reducers, essential fittings used in piping systems to seamlessly connect

What is a Butt Weld Concentric Reducer At SINO SPECIAL METAL, we offer high-quality butt weld concentric reducers, pivotal components

SSM stands as a premier supplier enterprise, renowned for its specialization in crafting high-quality special metal products. Our commitment to excellence and precision in production ensures that your unique metal requirements are not just met but exceeded. Discover the quality that defines SSM as a leading name in the industry.