What is a butt weld elbow? A butt weld elbow is a type of pipe fitting used to change the

Butt weld fittings are crucial components in piping systems used to connect pipes of various diameters and sizes seamlessly. They facilitate a secure, leak-proof joint by welding the fitting directly to the pipe end. These fittings are designed to withstand high pressure, temperature, and corrosive environments, ensuring reliability in diverse industrial applications.

Size Range: Butt weld fittings come in various sizes, ranging from small diameters to large sizes, catering to diverse piping requirements.

Standards: They adhere to international standards such as ASTM, ASME, ANSI, DIN, and others, ensuring compatibility and reliability in various applications.

Thickness : Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc.

Dimensions : ANSI/ASME B16.9, B16.28, MSS-SP-43.

Size : Seamless ( 1/2″~24″), ERW / Welded / Fabricated Elbow (1/2″~48″)

Form : Pipe Tee, Equal Tee, Unequal Tee, Lateral Tee, Straight Tee, Reducer Tee, Seamless Tee, Welded Tee

Type : Seamless / Welded / Fabricated

Butt weld fittings are available in a wide range of materials and grades to suit different application requirements:

Stainless Steel Tee :

ASTM A403 WP 304/ 304L/ 304H/ 316/ 316L/ 317/ 317L/ 321/ 310/ 347/ 904L

Carbon Steel Tee :

ASTM A234 WPB / A420 WPL3/ A420 WPL6/ MSS-SP-75 WPHY 42/46/52/56/60/65/70

Alloy Steel Tee :

ASTM A234 WP1/ WP5/ WP9/ WP11/ WP22/ WP91

Nickel Alloy Tee :

ASTM / ASME SB 336 UNS 2200 (Nickel 200), UNS 2201 (Nickel 201), UNS 4400 (Monel 400), UNS 8020 (Alloy 20 / 20 CB 3, UNS 8825 Inconel (825), UNS 6600 (Inconel 600), UNS 6601 ( Inconel 601), UNS 6625 (Inconel 625), UNS 10276 (Hastelloy C 276)

Duplex & Super Duplex Steel Tee :

ASTM A815, ASME SA815 UNS NO S31803, S32205. Werkstoff No. 1.4462

Copper Nickel Tee :

CuNi10Fe1Mn, CuNi30Mn1Fe.

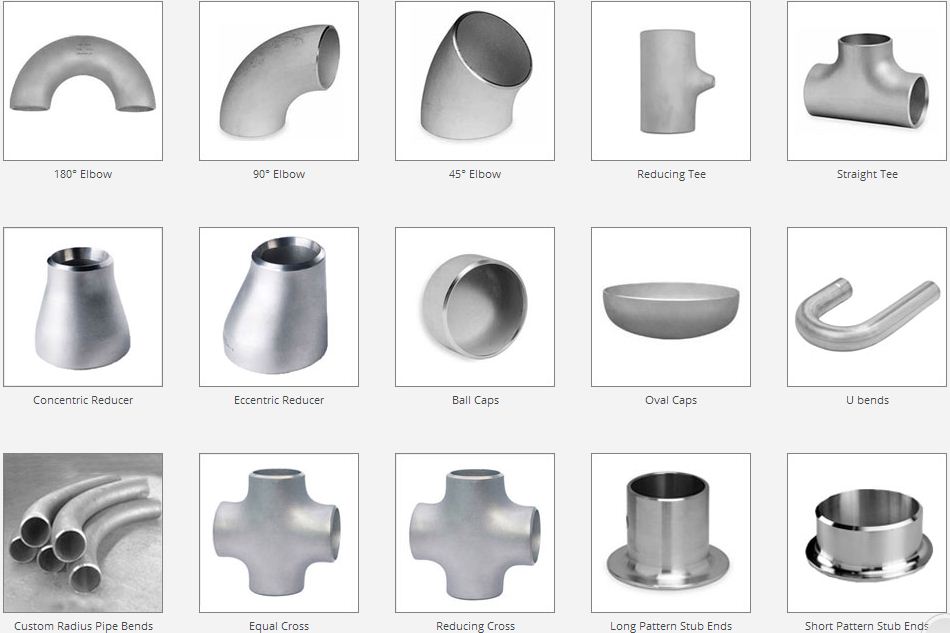

Butt weld fittings come in various types, each serving specific functions in piping systems. Here are some common types:

1. Butt Weld Elbows:

– 90° and 45° Elbows: Used for changing the direction of piping, facilitating smooth flow or direction changes without significant pressure drops.

2. Butt Weld Tees:

– Equal Tees: Used to create branches or junctions in pipelines with equal diameters.

– Reducing Tees: Connect pipes of different diameters, allowing for a larger or smaller flow into the main pipeline.

3. Butt Weld Reducers:

– Concentric Reducers: Gradually reduce the pipe size while maintaining a central alignment for smooth fluid flow.

– Eccentric Reducers: Provide a transition between pipes of different diameters while maintaining an offset between the centerlines.

4. Butt Weld Caps:

– End Caps: Used to seal the end of a pipe, preventing the flow of liquids or gases. They are often used for inspection or maintenance purposes.

5. Butt Weld Crosses:

– Equal Crosses: Provide a four-way connection for pipelines with equal diameters at all ends.

– Reducing Crosses: Allow connections between pipes of different diameters, forming a four-way intersection.

6. Butt Weld Stub Ends:

– Stub Ends: Used in conjunction with lap joint flanges to create a detachable connection, allowing easy disassembly for maintenance.

7. Butt Weld Couplings:

– Full Couplings: Join two pipes of the same diameter, extending the pipeline length.

– Half Couplings: Welded onto one end to connect smaller pipes or fittings.

8. Butt Weld Olets:

– Weldolets: Provide an outlet connection from a larger pipe to a smaller one, reducing the need for additional fittings.

9. Butt Weld Lateral Tees:

– Lateral Tees: Used when a pipeline requires a branch at a 45° angle rather than a straight 90° tee connection.

10. Butt Weld Nipples:

– Hex Nipples: Short lengths of pipe with male threads on both ends for connecting two female-threaded fittings.

Each type of butt weld fitting serves a specific purpose in constructing and configuring piping systems, allowing for versatile and efficient designs while ensuring structural integrity and leak-free operations. These fittings are available in various materials, sizes, and configurations to suit diverse industrial applications and piping requirements.

Oil & Gas: Butt weld fittings find extensive use in oil refineries, petrochemical plants, and gas processing facilities for connecting pipes in critical operations.

Chemical Processing: Industries dealing with corrosive chemicals rely on these fittings to ensure leak-free connections and structural integrity.

Power Generation: Butt weld fittings play a pivotal role in power plants, handling high-pressure steam and water systems.

Shipbuilding: Marine applications require reliable fittings to withstand corrosive seawater and maintain the structural integrity of piping systems onboard ships.

Advantages:

Reliability: Butt weld fittings provide a strong, permanent connection, reducing the risk of leaks and ensuring system integrity.

Versatility: Available in various sizes, types, and materials, offering flexibility in meeting diverse industrial requirements.

Durability: Designed to withstand high pressure, temperature, and corrosive environments, ensuring long-term performance.

Manufacturers follow stringent quality control processes, including material testing, dimensional checks, and weld examinations, to ensure that butt weld fittings comply with industry standards and meet performance expectations.

As SINO SPECIAL METAL, we specialize in supplying high-quality butt weld fittings crafted from premium materials such as carbon steel, stainless steel, and alloy steel. Our fittings meet rigorous specifications, ensuring compatibility, reliability, and durability in critical piping systems across diverse industries, including oil and gas, chemical processing, power generation, and shipbuilding. We prioritize quality, reliability, and customer satisfaction in delivering fittings that meet the stringent demands of industrial applications.

What is a butt weld elbow? A butt weld elbow is a type of pipe fitting used to change the

At SINO SPECIAL METAL, we provide high-quality butt weld eccentric reducers, essential fittings used in piping systems to seamlessly connect

What is a Butt Weld Concentric Reducer At SINO SPECIAL METAL, we offer high-quality butt weld concentric reducers, pivotal components

SSM stands as a premier supplier enterprise, renowned for its specialization in crafting high-quality special metal products. Our commitment to excellence and precision in production ensures that your unique metal requirements are not just met but exceeded. Discover the quality that defines SSM as a leading name in the industry.