What is a butt weld elbow? A butt weld elbow is a type of pipe fitting used to change the

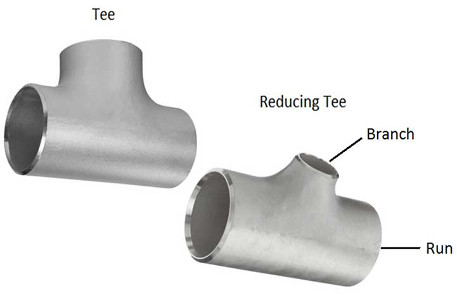

Butt weld tees are essential fittings used in piping systems to create branches or junctions, allowing the flow of fluids or gases in different directions. They are characterized by a T-shaped structure, enabling a 90-degree branch connection between pipes of equal or varying diameters.

Butt weld tees are manufactured according to industry standards such as ASTM, ASME, ANSI, and MSS, ensuring uniform dimensions and compatibility with diverse piping configurations. They are available in various sizes, schedules, and pressure ratings, meeting specific project requirements.

Thickness : Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc.

Dimensions : ANSI/ASME B16.9, B16.28, MSS-SP-43.

Size : Seamless ( 1/2″~24″), ERW / Welded / Fabricated Elbow (1/2″~48″)

Form : Pipe Tee, Equal Tee, Unequal Tee, Lateral Tee, Straight Tee, Reducer Tee, Seamless Tee, Welded Tee

Type : Seamless / Welded / Fabricated

Butt weld tees come in various types and configurations to suit different piping needs. Here are some common types:

1. Equal Tee:

– Equal Butt Weld Tee: Also known as straight tees, these fittings have three equally-sized openings, providing a 90-degree branch connection between pipes of the same diameter.

2. Reducing Tee:

– Reducing Butt Weld Tee: These tees have one opening larger than the other two, allowing for a branch connection between pipes of different diameters. They facilitate the transition between larger and smaller pipelines.

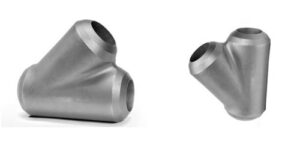

3. Lateral Tee:

– Butt Weld Lateral Tee: With a 45-degree branch angle, these tees enable branching at an angle rather than the standard 90-degree orientation. They are used in applications where a gradual flow diversion is required.

4. Barred Tee:

– Butt Weld Barred Tee: These tees have a bar welded internally, allowing flow in two directions while blocking the third direction. They are useful in applications where flow needs to be controlled or diverted selectively.

5. Split Tee:

– Butt Weld Split Tee: These tees consist of a T-shaped fitting with one end cut open and can be welded to an existing pipe without the need for disassembly. They are used for modifications or repairs in existing piping systems.

6. Double Branch Tee:

– Butt Weld Double Branch Tee: Featuring two branch openings, these tees enable two pipes to join a main pipe at a 90-degree angle, providing a dual branch connection.

7. Combination Tee:

– Butt Weld Combination Tee: These tees combine different types of branches, such as an equal tee combined with a reducing tee on one side, offering versatility in piping configurations.

8. Flanged Branch Tee:

– Butt Weld Flanged Branch Tee: Incorporating flanges on the branch connections, these tees allow for easier installation and disassembly without welding, suitable for applications requiring periodic maintenance.

9. Insulated Tee:

– Butt Weld Insulated Tee: These tees are designed with thermal insulation to prevent heat loss or condensation in piping systems used for temperature-sensitive substances or in environments with varying temperatures.

10. Extruded Outlet Tee:

– Butt Weld Extruded Outlet Tee: These tees have an extruded outlet welded onto the main pipe, providing a smooth flow path with reduced turbulence and minimizing stress concentrations.

Each type of butt weld tee serves a specific purpose in piping systems, catering to diverse industrial requirements. They are available in various materials, sizes, and configurations to accommodate different pipe diameters, fluid types, pressure ratings, and environmental conditions, ensuring efficient and reliable operations in various applications across industries.

These tees are crafted from different materials to suit diverse industrial applications:

– Carbon Steel: ASTM A234 WPB, WPC

– Stainless Steel: ASTM A403 WP304/304L, WP316/316L

– Alloy Steel: ASTM A234 WP1, WP5, WP9, WP11, WP22

Different material grades offer varying levels of corrosion resistance, strength, and temperature tolerance to cater to the demands of different industries.

Industry Applications:

– Oil & Gas: Butt weld tees find extensive usage in oil refineries, petrochemical plants, and gas processing facilities for creating branches in pipelines, enabling efficient fluid flow.

– Chemical Processing: Industries dealing with chemicals utilize these tees to direct flow into various processing units or equipment.

– Power Generation: Power plants employ butt weld tees to manage and control the flow of steam, water, or other fluids in complex piping systems.

– Construction & Infrastructure: These fittings are utilized in various construction projects, including building plumbing systems and HVAC applications.

– Versatility: Available in equal and reducing configurations, accommodating different pipe diameters and flow requirements.

– Reliability: Ensures a strong, leak-free junction, maintaining the integrity of the piping system.

– Compatibility: Offers compatibility with other butt weld fittings, facilitating seamless integration within complex piping networks.

Manufacturers adhere to stringent quality control procedures, including material testing, dimensional checks, and weld examinations, to ensure that butt weld tees conform to industry standards and meet performance expectations. This ensures reliability and longevity in service.

As SINO SPECIAL METAL, we specialize in supplying high-quality butt weld tees manufactured from premium materials. Our range of tees conforms to industry standards, ensuring compatibility, reliability, and durability in critical piping systems across diverse industries, including oil and gas, chemical processing, power generation, and construction. We are committed to providing top-notch products that meet the rigorous demands of industrial applications, prioritizing quality, precision, and customer satisfaction.

What is a butt weld elbow? A butt weld elbow is a type of pipe fitting used to change the

At SINO SPECIAL METAL, we provide high-quality butt weld eccentric reducers, essential fittings used in piping systems to seamlessly connect

What is a Butt Weld Concentric Reducer At SINO SPECIAL METAL, we offer high-quality butt weld concentric reducers, pivotal components

SSM stands as a premier supplier enterprise, renowned for its specialization in crafting high-quality special metal products. Our commitment to excellence and precision in production ensures that your unique metal requirements are not just met but exceeded. Discover the quality that defines SSM as a leading name in the industry.