What is a butt weld elbow? A butt weld elbow is a type of pipe fitting used to change the

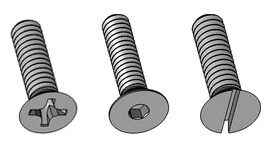

Flat head screws are a type of fastener characterized by a flat or countersunk head designed to sit flush with the surface of the material into which they are driven. They are widely used in various applications, especially where a smooth, even surface is desired.

1. Slotted Flat Head Screws: These screws have a single slot on the head, requiring a flat-blade screwdriver for installation. They are among the oldest and most traditional types of screws.

2. Phillips Flat Head Screws: Featuring a cross-shaped recess on the head, Phillips screws require a Phillips screwdriver. They offer better torque application compared to slotted screws.

3. Torx (Star) Flat Head Screws: These screws have a six-pointed star-shaped recess on the head, providing enhanced torque transfer, reducing cam-out, and minimizing the risk of damage to the screw or the driver.

4. Square Flat Head Screws: These screws have a square-shaped recess on the head, providing a more secure fit for the screwdriver bit, reducing the risk of slippage and increasing torque.

5. Hex Socket (Allen) Flat Head Screws: Featuring a hexagonal-shaped recess, these screws require an Allen wrench or hex key for installation. They provide high torque transfer and are commonly used in applications where space is limited.

1. Head Design: Flat head screws have heads that are flat or countersunk, allowing them to sit flush with the material’s surface. The variations lie in the shape of the recess or slot on the head, determining the type of screwdriver or tool needed for installation.

2. Torque Application: Different types of recesses or slots on the heads affect the ease of torque application. Phillips, Torx, square, and hex socket heads often provide better torque application compared to traditional slotted heads, reducing the risk of cam-out (the driver slipping out of the recess).

3. Cam-Out Prevention: Some modern screw types, like Torx and hex socket screws, are designed to reduce cam-out, preventing damage to the screw or the tool.

4. Appearance and Aesthetics: The type of head can also impact the visual appearance of the fastened surface. Flat head screws offer a flush or countersunk appearance, while the choice of recess or slot can impact aesthetics.

Each type of flat head screw has its advantages in terms of torque application, resistance to cam-out, and appearance, allowing for various applications across industries and preferences based on specific requirements.

Flat head screws are available in various sizes, catering to diverse applications. Common sizes include:

– 2, 4, 6, 8, 10: Representing smaller screw sizes.

– 1/4″, 3/8″, 1/2″, 5/8″, 3/4″: Representing larger screw sizes.

– Metric Sizes: M2, M3, M4, M5, M6, etc., denoting the diameter in millimeters.

These sizes correspond to different lengths and thread pitches for specific applications.

Specifications for flat head screws are often defined by industry standards such as:

1. ASME B18.6.3: This standard specifies the dimensions, tolerances, and mechanical properties of flat head screws, including slotted and recessed types.

2. ISO 2009: This international standard provides guidelines for slotted flat countersunk head screws and recessed flat countersunk head screws, detailing their dimensions and tolerances.

Flat head screws offer several advantages:

1. Flush Mounting: The flat head design allows these screws to sit flush with the material’s surface, providing a smooth finish and reducing snagging.

2. Countersinking Capability: Their design enables the screws to be countersunk, creating a recessed hole that accommodates the screw head, allowing for a flush surface.

3. Versatility: Flat head screws are versatile and can be used in various materials like wood, metal, plastic, and composites.

Flat Head Screw Availability:

Flat head screws are available in different materials, including:

– Stainless Steel: Offering corrosion resistance suitable for outdoor and marine applications.

– Alloy Steel: Known for strength and durability, suitable for heavy-duty machinery and automotive applications.

– Brass: Used in decorative applications due to its aesthetic appeal and corrosion resistance.

– Aluminum: Lightweight and corrosion-resistant, suitable for aerospace and automotive industries.

– Titanium: Known for its high strength-to-weight ratio and corrosion resistance, used in aerospace and medical applications.

Sino Special Metal and Supply of Flat Head Screws:

At Sino Special Metal, we specialize in providing an extensive range of industrial fasteners, including flat head screws, across different sizes, materials, and specifications.

Our Offerings:

We offer flat head screws in various materials to cater to specific industry needs. Our inventory includes stainless steel, alloy steel, brass, aluminum, titanium, and other specialty materials.

Quality Assurance:

Quality is paramount at Sino Special Metal. Our flat head screws undergo rigorous quality checks and comply with industry standards such as ASME and ISO, ensuring optimal performance and durability in various applications.

Custom Solutions:

Understanding the diverse needs of different industries, we provide customizable solutions for flat head screws, catering to specific size requirements, materials, coatings, and finishes.

Prompt Delivery:

Our efficient supply chain management ensures prompt delivery of products, meeting our customers’ timelines and project requirements.

Flat head screws offer flush mounting, countersinking capability, and versatility in various materials. Sino Special Metal’s commitment to quality, customization, and timely delivery ensures a wide range of flat head screws in different materials, meeting industry standards and providing tailored solutions for various applications.

What is a butt weld elbow? A butt weld elbow is a type of pipe fitting used to change the

At SINO SPECIAL METAL, we provide high-quality butt weld eccentric reducers, essential fittings used in piping systems to seamlessly connect

What is a Butt Weld Concentric Reducer At SINO SPECIAL METAL, we offer high-quality butt weld concentric reducers, pivotal components

SSM stands as a premier supplier enterprise, renowned for its specialization in crafting high-quality special metal products. Our commitment to excellence and precision in production ensures that your unique metal requirements are not just met but exceeded. Discover the quality that defines SSM as a leading name in the industry.